HVAC Coils

HVAC Coils – The Heat Exchangers Of Your System

Home >Our Products >HVAC Coils

Heat exchangers are essential part of all HVAC systems for heat transfer and exchanging. Proper and optimise design will protect prolong lifespan of equipment as a whole and preserve converse more energy.

○ Ideal Coil For Your Requirement

There are multiple coil types to pick from, and each one has its unique advantages. Air Royal can assist you in choosing the ideal coil for your air quality and climate control requirements.

○ Improved Performance & Energy Efficiency

There are multiple coil types to pick from, and each one has its unique advantages. Air Royal can assist you in choosing the ideal coil for your air quality and climate control requirements.

We are also dealing with more towards money back and performance guarantee on air-side. Should there be any retrofit works on air-side to reduce electrical consumption, we do hope we be given the opportunity to do a presentation to you and your team on how can we save you energy with performance and money back guarantee.

In summary we will stated in our quotation that if after our rectification and there is no improvement and no energy savings, we will not collect a single cent. No questions asked if performance not met.

We would like to take this opportunity to highlight problems being faced by most and many building owners are as follows :

1) About 40% to 50% of the total energy consumed by air-conditioning in all buildings worldwide is used for space heating and cooling. Many owners are wasting unnecessary energy without them knowing too. Why?

2) Because most owners are layman and they leave the decision of equipment selection to contractors and consultants to do equipment sizing base on manufacturers’ (York, Carrier, Trane and etc) catalogue for equipment selection which is not advisable and not the best solution for the reason that

- 2a) For example, they select that particular unit and look at the cooling capacity (kW) to select from catalogue, but forgetting that in order to achieve the cooling capacity, the incoming source flow must be sufficient, then is able to derive to achieve the desired capacity. What happen if some existing buildings with insufficient existing incoming flow source? Thereafter, owners have to again spend additional to upgrade existing incoming flow source which will turn out to be even wasting more time and input again additional unnecessary capital.

- 2b) Some building oversized their existing incoming flow source which is also wasting unnecessary energy and electrical consumption, which actually they could use much lesser energy to perform the same cooling. A recent example case study is Roche, a pharmaceutical plant. Before replacement of the Air Handling Unit (AHU) chilled water cooling coil, the modulating valve is 100% fully opened. After our optimisation, the valve opening resulted in 30% opened only. Means to say that less chilled water is being used to perform the same cooling, and that will indirectly affect the pump to ramp down and save more energy. More to that is that if the load is not required that much, the chiller will ramp down and run lower in part load and that contribute in even more energy savings.

3) All buildings are as-built from day one with air-conditioning are being installed, left with limited access. Through our detailed and precision engineering, and planning, we are able to make the impossible possible to get the existing equipment replaced without need of hacking, optimise it and perform much lower energy consumption than before.

The beauty of air side energy design optimization is that no single system is the same. Whenever we agree on a partnership with a new client, we spend a lot of time evaluating their air side system across all areas to determine what parts are currently working well, which areas need improvement and strengthening the most. We believe every client has a right to GET THE BEST and most out of your investments and the highest quality of service. Together with Air Royal, we can play our part in making Earth a Greener Place.

Types Of HVAC Coils

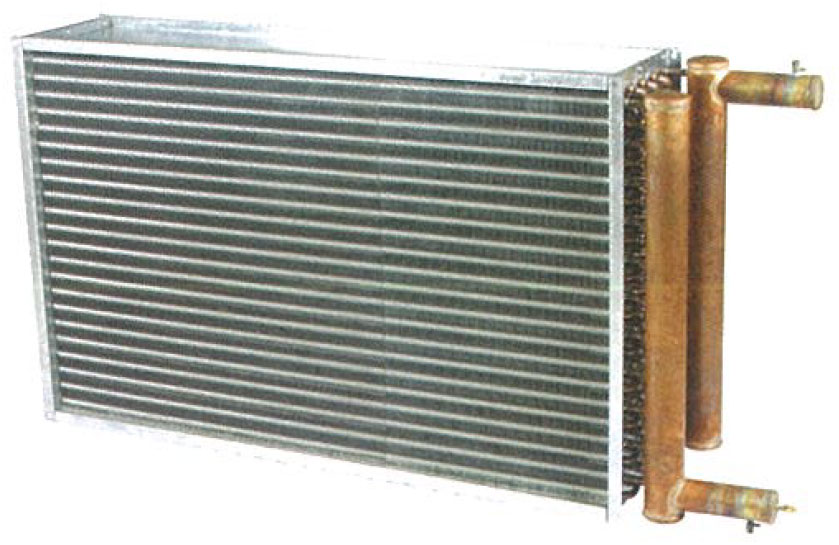

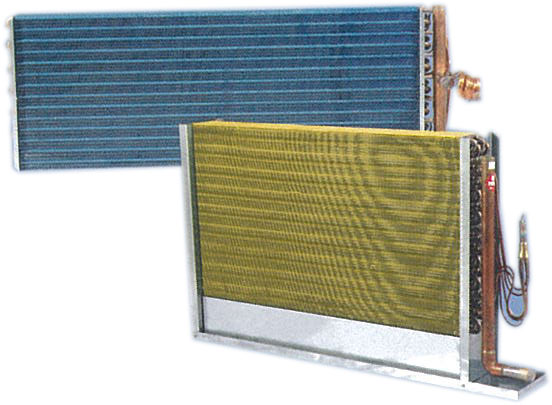

Chilled Water Coils/ Hot Water Coils

Water coils can be chilled/cooling, hot/ heating, reheat, run around or pre-cooled coils designed to meet a wide range of cooling, heating and reheating needs.

Evaporator Coils

Evaporator coils are designed to withstand wide range of temperatures, from normal air-conditioning condition to sub-zero freezing applications for medicine processing, food, cold room storage and other purposes.

Condenser Coils

Condenser coils are one of the essential key components needed for an air-cooled unit/chiller to heat reject to function. If it malfunctions or leaks, system will not be able heat exchange to provide cooling to your requirement. Failure to ensure good system in place will result in major and heavy repair cost.

Pre-Coated, Hydrophobic, Hydrophilic, Glass Coated Fins, Tio2, Epoxy & Etc

Depending on different applications, we will propose the best suitable coating to preserve, protect and prolong your life cycle assets. Having a good protection, it will also help maintain consistent electricity consumption. Corroded/Oxide coils will result in higher than usual electricity consumption and shorten lifespan of the equipment as a system.

Copper Fin

Copper fin coils are required for air conditioning in extremely corrosive environment like refinery, oil & gases, chemical rooms, coastal areas and etc.

Coils' Certification

We provide coils that meet the strictest quality standards for design and manufacturing outlined in Canadian standard CSA B51

This marking is a mandatory European marking for certain product groups to indicate conformity the essential health and safety requirements set of European Directives

Air Conditioning Heating And Refrigeration Institute (”AHRI”)

All coil products have been certified in accordance with AHRI Standard 410-2001. Certificate from the Department of Industrial

Standard accreditation of quality at the level of high pressure not exceeding 420 PSI (Pound Per Square Inch)

The US standard accreditation of quality at the level of high pressure not exceeding 540 PSI of all product models

We are expert in providing the best solutions for you.