Adsil Advanced Siloxane

Coating System

Protection against corrosion, mold growth, chemicals, heat, UV light, pollution and more

Home >Our Products >UV Light

Introducing the Next Generation HVAC Coating achieving 25, 300 hours ASTM B117 mark surpassing on worldwide record.

| Coating Comparison | MicroGuard-3500 HVAC/R Coating | Traditional HVAC Coatings |

|---|---|---|

| Coating Chemistry | In-Organic | Organic |

| Bond Strength | 193.5 (33% Stronger) | 145 |

| Degraded by Heat, Light or Oxygen | No | Yes |

Preserve

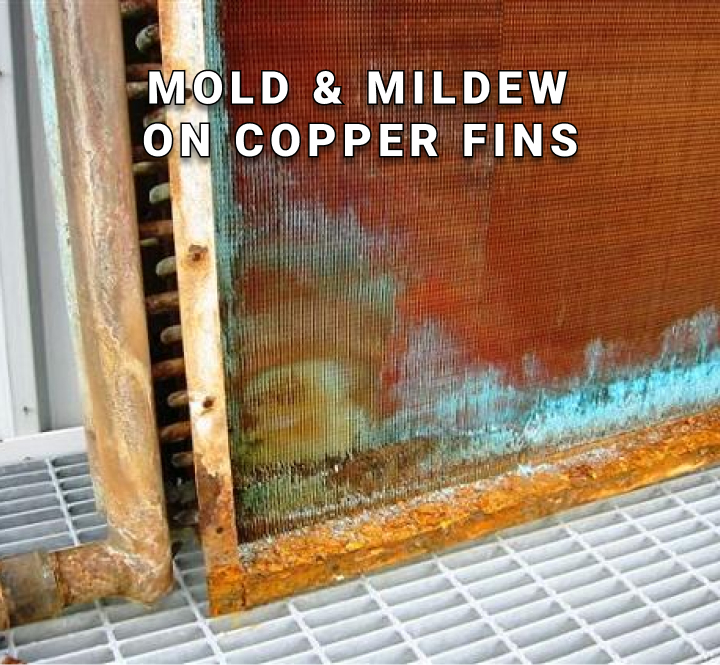

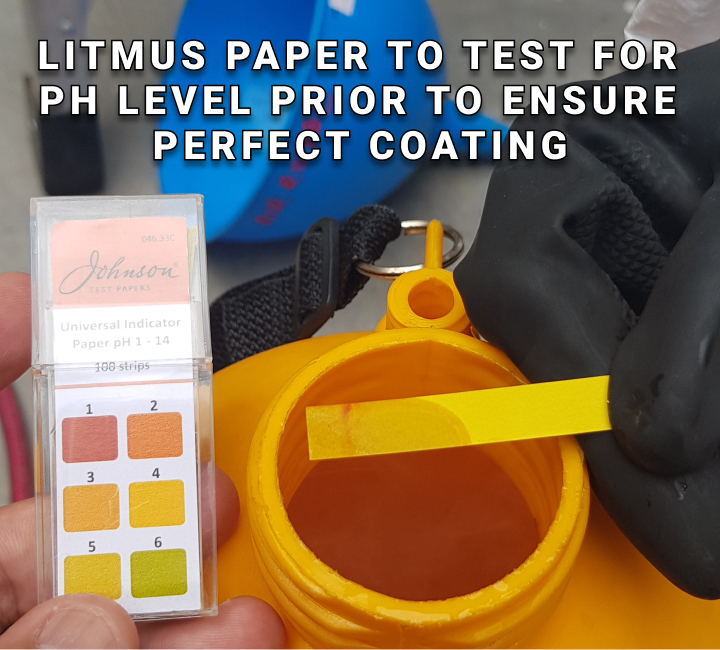

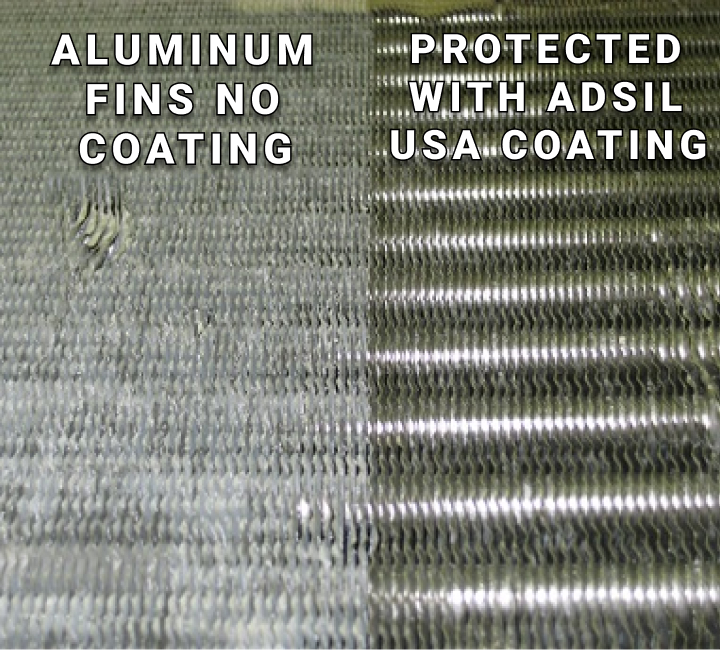

MicroGuard1-3500 is an inorganic cross link cured, glass-like film that chemically bonds to non-ferrous metal ensuring maximum adhesion and protection in the harshest environments. At 6-8 microns thick, the coating preserves your HVAC/R system’s original performance without affecting heat transfer or laminar air flow.

Prolong

MG1-3500 can prolong your HVAC/R system beyond its normal engineered life expectancy, extending the replacement cycle and capital budget outlay. Deferred capital expenses and provided energy savings drop directly to the bottom line.

Prolong

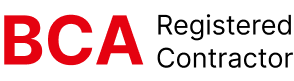

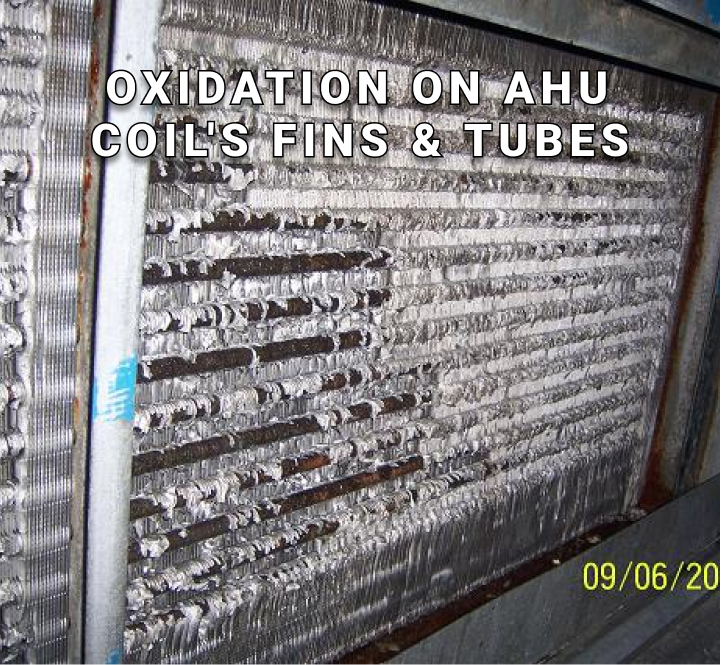

MG1-3500 offers superior corrosion protection, but it doesn’t stop there! MG1-3500’s advanced formula protects against pollution and chemical assault other coatings can’t, cannot oxidize, will not support mold growth improving indoor air quality. Its hydrophobic properties repel debris, reduce maintenance and save energy protecting your assets and your bottom line.

Superior Quality

Adsil’s MG1-3500 Inorganic Coating is much superior than the Traditional Organic Coatings

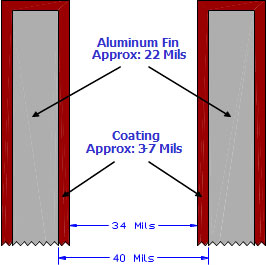

Traditional Organic Coatings

Conventional HVAC/R Coatings are Organic and Thick (3-7 mils / 127 microns)

- Organic formula feeds mold and microbes

- Airflow passage is reduced due to coating thickness

- Pressure drop across the coil increases

- Higher fan power consumption

- Heat Transfer efficiency is reduced

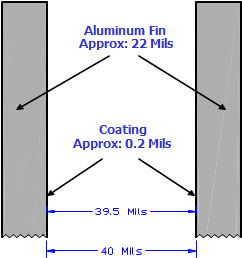

Adsil’s MG1-3500 Inorganic Coating

Adsil’s MG1-3500 HVAC/R Coating is Inorganic and Thin (0.2 mils / 7 microns)

- Inorganic formula will not feed mold and microbes

- No airflow reduction

- Will not increase pressure drop across the coil

- Lower fan power consumption

- Heat transfer efficiency is constant

We are expert in providing the best solutions for you.